Cross flow membrane filtration is an important stage in clarification processes, helping to produce high-quality products but maintaining complex flavour profiles and brand characteristics. Cross flow membranes are critical components for beer and wine filtration equipment removing microbes and suspended solids to improve product clarity, taste and shelf life.

All cross flow membranes have a finite lifespan and start to deteriorate over time. As they reach the end of their natural life, quality standards start to decrease, yields reduce and more energy and chemicals are needed to deliver the outputs required.

Envirogen’s Envi ranges of replacement beer membrane filters (BMF) and wine membrane filters (WMF) are designed to fit a wide range of beer and wine filtration equipment, including Envirogen’s own PureSep MF micro-filtration systems and Pentair and Pall models.

Envi-BMF and Envi-WMF polypropylene membranes are designed for long life and provide increased membrane performance when measured against leading competitor and original equipment manufacturer (OEM) brands. Offering increased flow rates and greater batch volumes, Envi-WMF and Envi-BMF cross flow membranes combine decreased capital outlays with lower operating costs.

Process-specific cross flow membranes for beer and wine filtration

Envi hollow fiber cross flow membranes are the result of Envirogen’s many years of experience in designing and installing beer and wine filtration equipment and membranes.

Cross flow membrane filtration installation at Halewood winery in Liverpool, UK, complete with Envi-BMF membranes.

Envi-BMF and Envi-WMF polypropylene membranes offer increased flux rates when compared to polyvinylidene fluoride (PVDF) membranes. The increased 1.8 mm diameter lumen achieves greater concentrations and flow rates for improved batch volumes and reduced waste.

Envi-WMF direct replacement membranes for wine filtration equipment

Our Envi-WMF hollow fiber membranes are designed to fit our PureSep 100 wine filtration systems and variants can also be used as a cost-effective, direct replacement for Pall Oenoflow membranes in the following systems:

- Pall Oenoflow™ XLE/XLS XLA

- Pall Oenoflow™ FIT System

- Pall Oenoflow HS

Pall Oenoflow membrane skid fitted with Envi-WMF membranes in Italian winery. To date, the Envi-WMF membranes have filtered over 1 million hectolitres of wine.

Not only do Envi-WMF membranes provide a lower-cost solution to Oenoflow branded membranes, but they also provide increased flux-rates and greater batch volumes, reducing the amount of waste created.

Choose from the following two Envi-WMF models:

Envi-WMF 46 membrane

Module details |

||

| Membrane material | Polypropylene | |

| Membrane surface area | 17m² | |

| Pore size (nominal) | 0.2µm | |

| Capillary inner diameter | 1.8mm | |

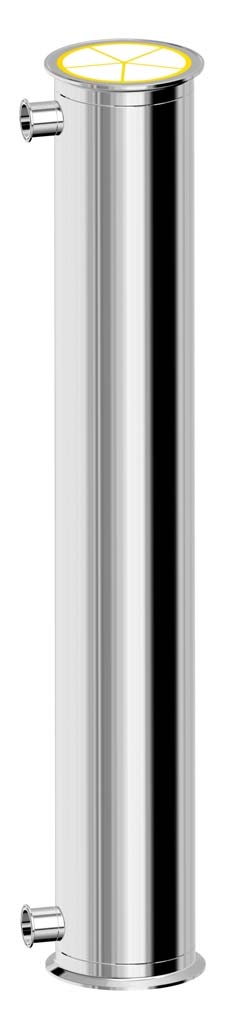

| Housing material | Stainless steel | |

| Potting material | Polyurethane | |

| Maximum housing pressure and temperature | 16 Bar at 50°C | |

Envi-WMF 66 membrane

Module details |

||

| Membrane material | Polypropylene | |

| Membrane surface area | 7.6m² | |

| Pore size (nominal) | 0.2µm | |

| Capillary inner diameter | 1.8mm | |

| Housing material | Stainless steel | |

| Potting material | Polyurethane | |

| Maximum housing pressure and temperature | 16 Bar at 50°C | |

Find the perfect wine filtration membranes for your clarification process.

Envi-BMF direct replacement membranes for beer filtration and clarification

Envi-BMF cross flow membranes are designed to fit our PureSep MF 600 beer clarification systems and can be used as direct replacements for Pentair membranes and skid systems, including:

- Pentair OptiBMF

- Pentair BMF 18

- Pentair BMF Compact

- Pentair BMF Compact 2

- Pentair Doubledecker (2x BMF18 on top of each other)

- Pentair Continuous BMF

The Envi-BMF polypropylene membrane design delivers a 10% increase in surface area when compared to the Pentair S-14 membrane. The wide lumen provides increased batch volumes at a lower operating cost.

Find the perfect Envi-BMF membranes for your beer clarification process.