Membrane optimisation services for all major filtration equipment including hollow fiber membranes and spiral wound membranes

Membrane filtration systems are a key component of many industrial processes. Filters, including hollow fiber membranes and spiral wound membranes, are used to perform many critical tasks, such as desalination, organic compound removal and the recycling and reuse of water and chemicals. Used throughout the water and production lifecycle, filtration has the potential to deliver huge cost and time savings, but without the proper maintenance and optimisation, it can deliver diminishing returns.

Membrane services from Envirogen

Envirogen’s service engineers are highly experienced in the installation, operation, familiarisation, maintenance and optimisation of all major membrane filtration systems, including Envirogen-own, Pentair membrane and Pall membrane skid systems.

Our local engineers are available throughout Europe offering fast service response times and stock to meet your process demands.

Our tailored membrane service packages are designed to ensure optimum performance and profitability. We deliver maximum service life for your membrane system through careful monitoring, targeted clean-in-place (CIP) regimes and considered chemical and membrane selection.

Our comprehensive membrane service packages include:

- Replacement membrane supply, installation, tooling and seals

- Process optimisation and troubleshooting

- Pilot plant supply for on-site trials and hire

- On-site and off-site CIP services

- Membrane diagnostics and repair services

- Training and plant familiarisation programmes

- Access to local engineers and expert advice throughout Europe

Membrane replacement

When membranes come to the end of their natural life, quality standards start to decrease, yields reduce and more energy and chemicals are needed to achieve required outputs.

As a supplier of a wide range of replacement membranes, we select the ideal product for your application. We understand your exact requirements, review the latest available technology and find the best solution to meet your filtration goals. Our spiral wound membranes and hollow fiber membranes are competitively priced and we offer additional discounts based on volume.

We’ll hold a large stock of high-quality membranes for nearly every kind of treatment system, often with next day dispatch from our warehouses in the UK and the Netherlands.

We supply:

- Hollow fiber membranes for:

- Spiral wound membranes for:

We stock large quantities of all membranes used in the manufacturer of our PureSep range of skids, along with a wide range of direct replacements for third-party skids.

Our membrane range includes:

Direct replacements for Pentair membranes:

- Pentair OptiBMF

- Pentair BMF 18

- Pentair BMF Compact

- Pentair BMF Compact 2

- Pentair Doubledecker (2x BMF18 on top of each other)

- Pentair Continuous BMF

Direct replacement for Pall membrane and Pall membrane filters:

- Pall Oenoflow™ XLE / XLS / XLA

- Pall Oenoflow™ FIT System

- Pall Oenoflow HS

PureSep microfiltration membranes

We offer a range of our own-brand microfiltration membranes to fit our PureSep crossflow microfiltration systems. Our microfiltration membranes are a great, cost-effective alternative to more expensive Pentair membrane and Pall membranes.

Envirogen replacement membranes tackle both CAPEX and OPEX, providing increased yields and higher quality standards at a lower cost when compared to Pentair membrane and Pall membrane equivalents.

Beer membrane filtration (BMF)

Envirogen’s PureSep MF is a direct replacement for the Pentair S-14 membrane. Envirogen’s ultra-efficient equivalent model features a 10% increase in surface area, compared to the Pentair membrane, providing greater batch volumes at a lower cost.

Learn how Molson Coors saved 40% on its process water volume and 35% on its energy bills with more efficient pumps and membrane replacements, recommended and installed by Envirogen

PureSep MF hollow fiber membrane filters for process filtration

Envirogen’s PureSep MF hollow fiber membrane filter is perfect for process filtration and is a direct replacement for the Pall hollow fiber membranes (five-inch and six-inch Microza models). With its increased lumen size, PureSep MF provides improved solids handling while the robust construction delivers increased permeability.

Contact our team of process experts to discuss your specific membrane requirements.

Optimisation programmes to suit your site and budget

Our teams are available on a project (ad-hoc day rate) basis or as part of a longer-term contract under our PureCare service offering.

We’ll tailor your plan to meet your requirements. By mapping the performance of your membranes over their serviceable life, we’ll advise the ideal replacement frequency, while alerting your team to any unusual activity. For example, by planning clean-in-place (CIP) sequences, we’ll maximise membrane life, while reducing downtime and increasing output. A carefully balanced chemical programme will ensure flux rates are fully restored post-CIP.

On-site and off-site CIP services

Regular CIP programmes extend membrane life and ensure quality standards are consistently met. We provide a range of on-site and off-site CIP services for most hollow fiber membrane technology and spiral wound membrane models.

Our CIP skids are available for easy on-site integration. These mobile cleaning systems, including RO membrane cleaning services, are a simple option for sites without existing CIP, restoring membrane performance and flux rates without disrupting your day-to-day activity. If you have your own on-site CIP system, Envirogen engineers are on hand to provide technical support and chemical supply.

For more challenging contamination issues, we also provide an off-site service. We’ll take fouled membranes to our nearest depo for more intensive cleaning processes, with longer soak cycles and specialised chemical treatment.

Contact your local team for more advice about our on-site and off-site CIP services.

Membrane diagnostics and repair services

Contamination can cause long-lasting membrane damage when left untreated, leading to performance issues and process downtime. When the contaminant is unknown, the issues can be difficult to locate and fix. We offer a complete membrane diagnostics service for both spiral wound membranes and hollow fiber membranes. Our team completes destructive testing on affected membranes, pinpointing the nature and type of fouling.

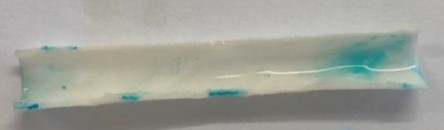

Example membrane on inspection

Example African Blue Dye testing post-chemical soak

Following diagnosis, we’ll create a full report detailing the inorganic and organic fouling elements, along with a chemical regime to remove contamination and restore flux-rates. A carefully detailed ongoing preventative maintenance plan will prevent future issues and protect your process.

Most hollow fiber membranes can be repaired. By bath testing fibers and applying a small amount of compressed air, we can identify damaged elements and advise on membrane repair options. Pins are then inserted into both ends of the fiber, taking it out of service. Up to 10 fibers can be pinned within each unit, ensuring water quality and greatly extending the overall life of the hollow fiber membrane.

Ask us about our range of on-site and off-site membrane diagnostics and repair services

Pilot plant for on-site microfiltration trials and hire; and off-site ultrafiltration testing

If you are looking to trial the latest technology for an existing process, or upgrade a conventional filtration process, we can demonstrate our technologies on-site while providing product samples for testing and confirmation.

Envirogen holds a range of pilot equipment in stock. We can offer on-site trialling of microfiltration technologies and an off-site, bench-top ultrafiltration testing service.

Contact our team for advice on your on-site trial plans.

For a free assessment to evaluate water treatment and process filtration solutions for your site, contact our team of expert engineers