With products available worldwide, the centre of this global brewer’s brand is consistency. Every bottle of beer or cider must taste the same, wherever it is produced. The drive for high quality starts with consistent product ingredients and it was this requirement that brought the drinks producer to Envirogen Group. Of particular interest to the client was our incoming water technology, generating purified water streams – using our ion exchange water softener systems – for a controlled method of specialty cider manufacturing.

Pure and consistent: a bespoke solution for a unique product

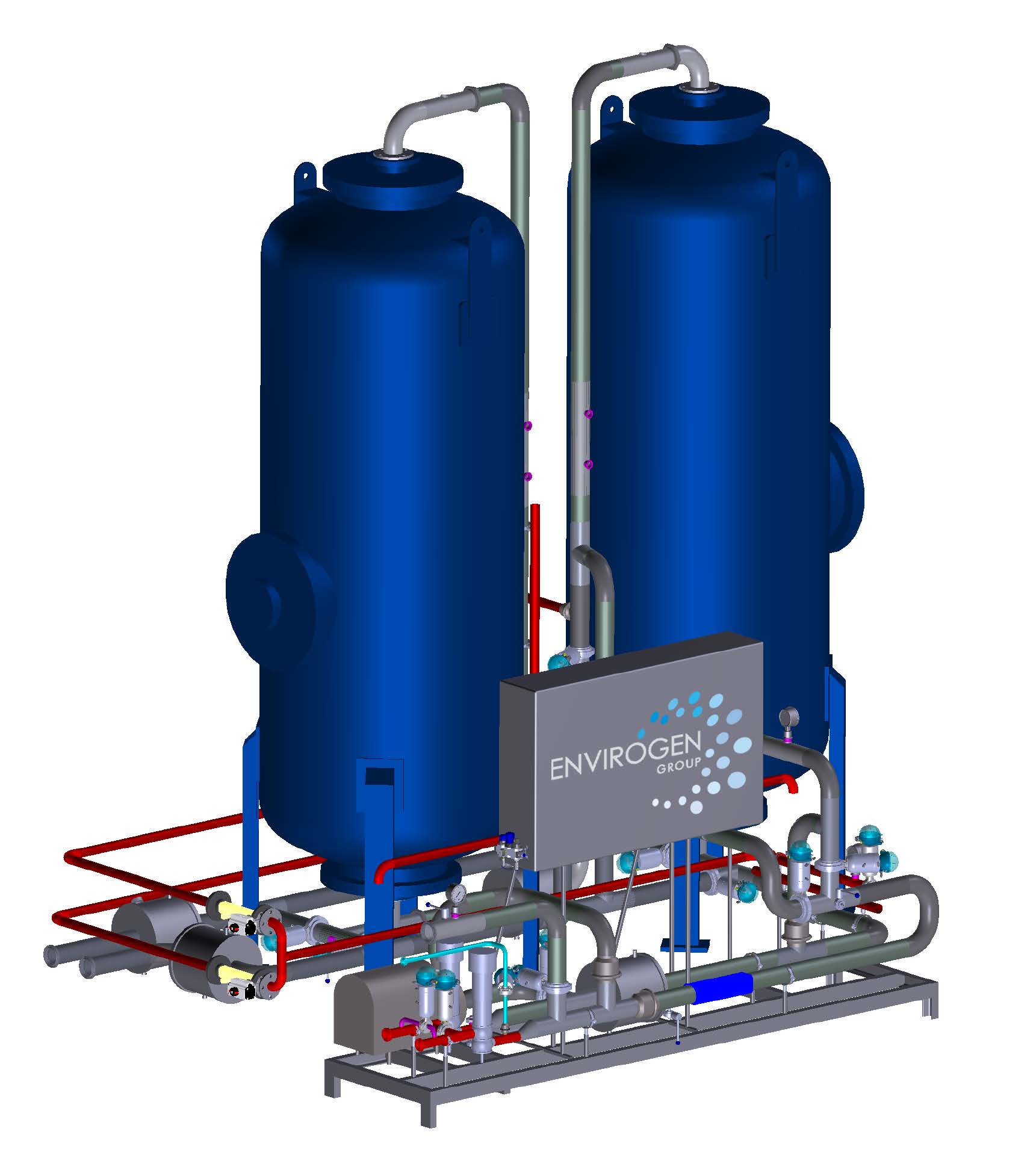

Bill Denyer, CEO Europe at Envirogen Group, explains: “To produce the consistent, pure and crisp taste we installed a two-stage skid-mounted ion exchange system contained within steel vessels, each with hygienic rubber lining to meet stringent food safety standards. The ion exchange water softener system removes dissolved salts and reduces the conductivity of the solution. Carefully selected salts are then added, in a specific recipe, to create the exact flavour profile, providing the pure, consistent liquor that is required for the final product.”

Final plant in situ

3D model of the designed system

“The ion exchange system provides a continuous supply of treated product until regeneration is required. To make the regeneration stage as quick and efficient as possible, we installed our own-brand duplex ion exchange water softener system, EcoSave, which provides a continuous supply of softened water. This softened stream enables very rapid regeneration of the ion exchange system, which maximises production time. The EcoSave is one of the most efficient water softeners on the market, using up to 50% less salt and 80% less water when compared to traditional softening systems. So, not only are we helping to ensure quality in the products, we are also helping the brewer meet its ambitious sustainability targets in reducing the amount of water it uses in manufacturing.”

“The whole system is future-proofed too. By adding another ion exchange water softener system, we can provide a duplex solution, ensuring that there is always a continuous supply of treated product, even when one system is regenerating.”

Tried and tested, then rolled out across territories

The brand had very clear reasons to use the Envirogen Group solution, which was first implemented in its European manufacturing centres and later into South East Asia. It was important that the solutions provider chosen for this work would have the capability to work across multiple territories. Not only did Envirogen have this capability, but it demonstrated the effectiveness of the solution in a very real way. Envirogen provided a fully functioning trial system at one of the client’s central European plants, validating that the solution met the client’s demanding requirements.

Trial plant on site in Europe

The Envirogen team provided detailed 3D diagrams for each site, demonstrating the integration with existing manufacturing equipment, and installed and integrated the entire system with no disruption to day-to-day operations. The client received the same consistent level of service at each of its European sites. The engineers stayed on site to fully commission the systems and train site operators in the control and operation of the new equipment and the input/output control systems on the ion exchange vessels ensure that the brewer has a high level of control over the entire process.

The brewer is now producing its trademark beverages across Europe and South East Asia. It has the same consistent high quality and taste as that produced in a UK factory, thanks to the very specific core concentrate that can now be produced locally.

Key outcomes

- A bespoke solution ensures that a unique product can be produced consistently across all manufacturing sites

- Proven results are driving simple transition across further geographical territories

- Rapid regeneration of the ion exchange water softener system results in a reliable supply of incoming purified water

- Efficient water softening technology is reducing salt usage by up to 50% and water usage by 80%, when compared to traditional water softening technology

For a free assessment to evaluate water treatment and process filtration solutions for your site, contact our team of expert engineers

About the client

The global brewer has a well-diversified geographic footprint with strong positions in 25 markets across Western Europe, Asia and Eastern Europe. Their beer portfolio spans core beer brands, craft and speciality and alcohol-free brews.