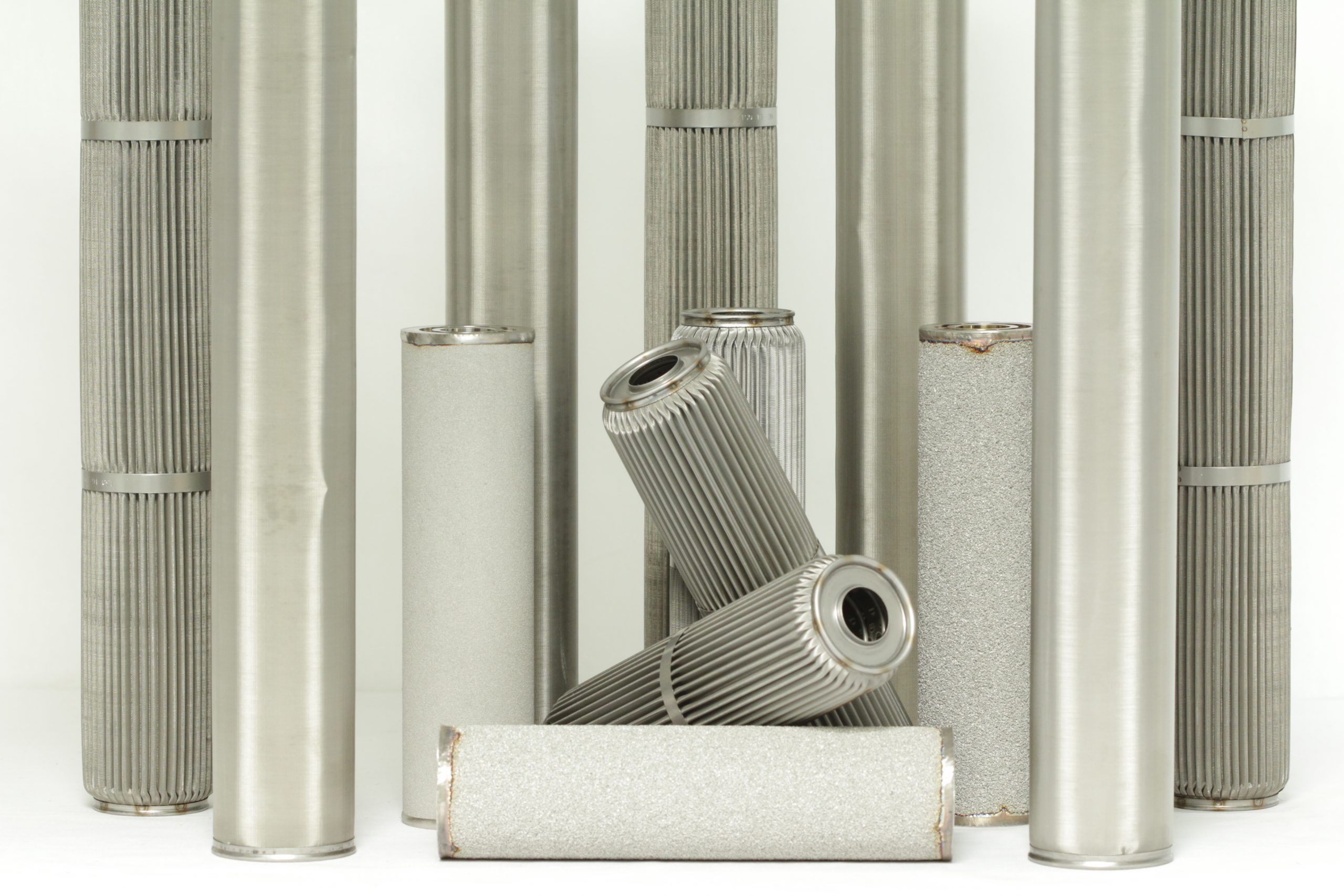

Our Flusint Fiber, Fluxamesh and Flusint Powder brands of stainless-steel, metal cartridge filters are designed for both liquid and steam filtration. These filter cartridges are ideal for use in extreme conditions, including elevated temperatures, high viscosity liquids and aggressive chemicals, and are suitable for most types of filter housings.

Flusint Fiber metal filter cartridges

Our Flusint Fiber metal filter cartridges are manufactured from sintered AISI 316L stainless steel microfibres.

Product details:

- Available as pleated or cylindrical models

- High flow rate – 20 times more than sintered stainless-steel powder cartridges – with low pressure drops

- High contaminant holding capacity

- High corrosion and temperature resistance

- High porosity at an average of 85%

- Filtration ratings: 1µm to 60µm

- Available in a variety of lengths: 4” to 40”

- Maximum operating temperature: 380°C for sintered fibres in AISI 316 – with alternative materials for higher temperatures

- Compatible with most filter housings

Typical applications:

- High viscosity liquids

- Steam

- High-temperature gases

- Hazardous fluids

- Fuel

- Inks

- Upstream vacuum pumping

- Catalysts and catalyst recovery

- Air and liquids in food and beverage manufacturing

Note: Because of the variables involved in pressure-drop value determination, including the vessel, type of cartridges, connections and fluids, please contact the Envirogen team for help on sizing.

Fluxamesh metal filter cartridges

Our Fluxamesh metal filter cartridges are manufactured from sintered AISI 316L or AISI 304 stainless steel microfibres.

Product details:

- Manufactured with wire mesh in AISI 304 or AISI 316 stainless steel

- Available in pleated or cylindrical models

- Filtration ratings: 5µm to 1000µm

Typical applications:

- High viscosity liquid filtration

- Fuels and lubricants filtration

- High-temperature gas filtration

- Potable and process water filtration

- Beverage filtration

- Detergent filtration

- Solvents filtration

Note: Because of the variables involved in pressure-drop value determination, including the vessel, type of cartridges, connections and fluids, please contact the Envirogen team for help on sizing.

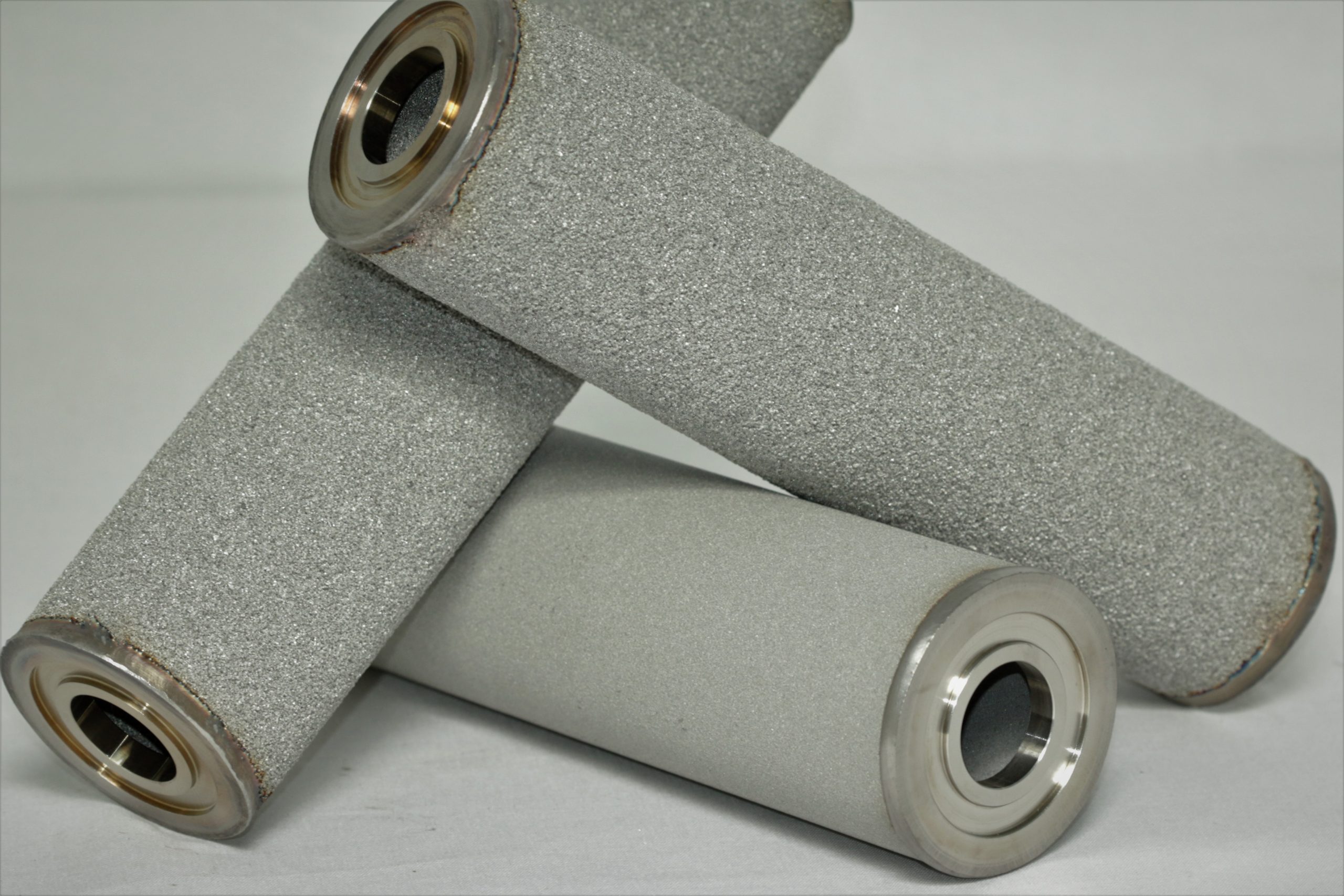

Flusint Powder metal filter cartridges

Our Flusint Powder metal filter cartridges are produced by high-temperature sintering of metal powder in AISI 316L. These depth filter cartridges have a maximum working temperature of 500°C, depending on the gasket material used, and have a high porosity of up to 50%.

Typical applications include:

- Steam filtration

- Liquid and gas filtration

- Catalyst powder recovery

- Precoat support filtration

Tailored filtration solutions and metal cartridge filters to meet your needs

With so many filtration options, it can be difficult to choose the metal filter cartridges and filter housings for your application.

Choosing the right solution depends on:

- Process temperature

- Type of liquid or gas medium

- Type and percentage of solids

- Operating and design pressures

- Desired particle removal size

- Size and micron ratings

- Viscosity of the fluid

- Available space

- Approvals process and regulatory requirements

- Other factors linked to your process/application

At Envirogen, we take a solutions-based approach to filter selection, we discuss your process filtration goals, understand your desired outcomes and give expert advice on metal filter cartridges, filter housings and consumables packages that best meet your needs.

Our team of process experts recommend solutions to maximise the effectiveness of your filtration process, enabling you to hit production and quality targets with a low total cost of ownership