Pressure leaf filters are a proven cake filtration technology that are installed in thousands of installations worldwide. While the filter vessels operate for decades, the filter leaves need to be replaced a few times during the lifetime of the vessel.

The quality and condition of your filter leaves are critical to the productivity and performance of your pressure leaf filter system. Replacing worn or damaged filter leaves will result in an immediate improvement in system performance.

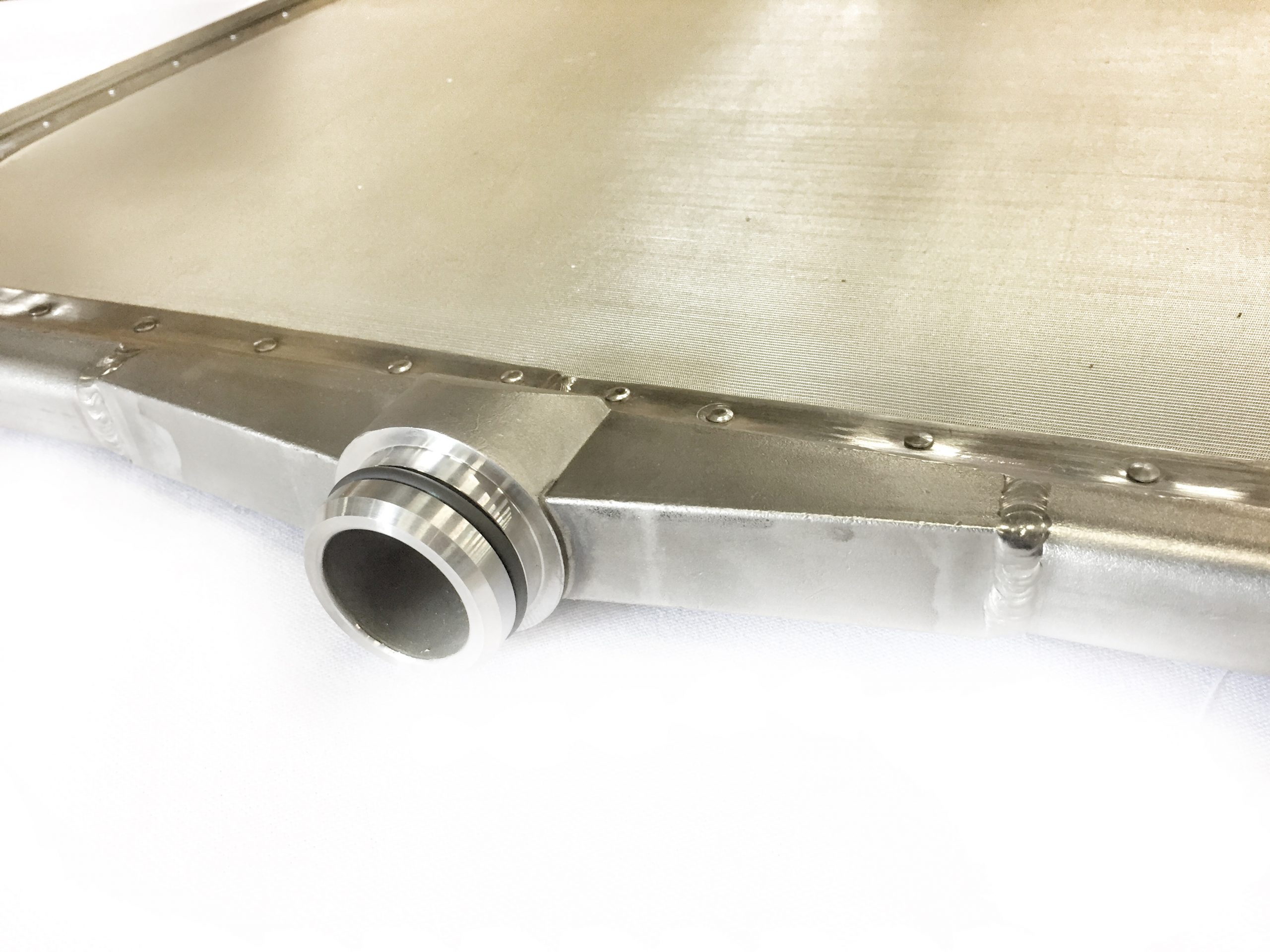

Envirogen offers high-quality filter leaves for almost every make or model of pressure leaf filter available on the market. Our Envi Leaf filters have a re-enforced box profile as standard with a five-layer mesh configuration and the very latest in high-flow nozzle technology.

Envi Leaf filter leaves can be used across a wide range of applications including:

- Edible oil processing (crude oil, bleached oil, winterised oil)

- Gelatine processing

- Pectin processing

- Glucose, sweeteners, sugar, fruit juice production

- Bio-diesel production (pre-treatment and polishing)

- Liquid sulphur filtration

- Chemicals and oleochemicals

- Organic and inorganic salts, amines, resins and bulk drugs

Our high-quality Envi Leaf filter leaves and filter plates come highly recommended and are available in a variety of materials, with a range of structures to suit every filtration task:

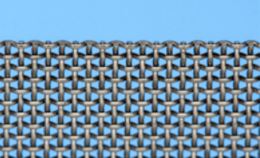

60 Mesh

- Plain weave filter screen

- Wire diameter: 0.19mm, 240µm

- Available materials: 316L, 317L, 904L stainless steel

24 x 110 Dutch weave

- Plain weave filter screen

- Wire shute diameter warp: 0.35mm, 0.25mm, 125µm

- Available materials: 316L, 317L, 904L stainless steel

PZ80 (reversed plain Dutch weave)

- Dutch weave filter screen

- Wire shute diameter warp: 0.35mm, 0.25mm, 90µm

- Available materials: 316L, 317L, 904L stainless steel

Envi Leaf filter leaves provide:

- Longevity – with five layers (ply) of stainless-steel wire mesh, each internal filter leaf is robust and designed for long-life.

- Reduced maintenance – delivering a low total cost of ownership.

- Years of service – long replacement periods mean that each leaf offers years of service.

- High-efficiency – with excellent pre-coating properties.

- Flexibility – Envi Leaf filter leaves can customise any filter vessel and can be used in multiple steps in the filtration process.

Order filter leaves and spare parts with our flexible stocking programme

A safe and secure supply of spare parts and replacements is an essential part of any manufacturing operation. With our flexible stocking programmes and technical expertise and advice, we’ll ensure delivery of spare parts and replacements when you need them, minimising interruption to your production cycle. We will work with you to develop a stocking system to meet your needs. Spare parts for pressure leaf filters and filter leaves can be held on your site or we can provide immediate dispatch from our warehouses for fast delivery.

Tailored filtration solutions to meet your needs

Selecting the right filter leaves for your application will depend on many factors like the flow rate, continuous or batch processing, the type and amount of solid load, the nature of the liquid, the temperature and the liquid viscosity.

Our team of process experts recommend solutions to maximise the effectiveness of your filtration process, enabling you to hit production and quality targets with a low total cost of ownership