Envirogen’s advanced metals removal system (AMRS) is an active water treatment system that allows use of multiple zero valent iron (ZVI) media formulations to accomplish the removal of heavy metals from wastewater – including selenium, chromium, and arsenic.

Our proprietary AMRS design achieves up to 50% lower capital cost compared to conventional ZVI system designs and provides the fluidization flow flexibility needed to utilise multiple types and grades of ZVI media formulations. Our design is unlike the in-situ approach more commonly employed with conventional ZVI for metals removal from water, and offers several advantages including:

- Reduced physical footprint

- Ability to effectively operate over a range of conditions and contaminant concentrations

- Automatic pH adjustment to optimise removal efficiency

- Pilot validation available and recommended

- Achieve permit compliance consistently

- Treated water can be safely discharged with no toxicity impact

Selenium, Chromium and Arsenic Removal: Envirogen’s Advanced Metals Removal System (AMRS) using FerroLock Zero Valent Iron (ZVI)

High efficiency: FerroLock™ zero valent iron media for removal of selenium, chromium and arsenic

Envirogen’s advanced metals removal system utilizes FerroLock™ ZVI technology to deliver highly efficient removal of selenium, chromium and arsenic from water allowing customers to comply with stringent wastewater discharge permit limits.

Envirogen’s approach is to examine the characteristics of your wastewater and select the best FerroLock™ ZVI media to use from an overall performance, longevity, and life cycle cost standpoint. We will consider concentrations of certain salts that can quickly dissolve the iron from some ZVIs. In addition, sulfate affects some ZVI formulations more than others.

Employed primarily for groundwater and wastewater remediation, our FerroLock™ ZVI media reacts with contaminants, effectively neutralising and adsorbing them, without generating toxic by-products.

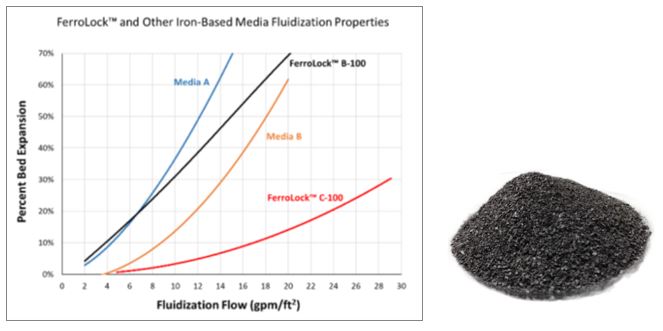

The ability of Envirogen’s AMRS to utilise different zero valent iron media that range in size, reactivity and cost is a unique benefit for you to consider.

FerroLock™ media key characteristics:

- High surface area

- Mechanisms employed are adsorption and chemical reduction

- Insoluble metals and iron-metal complexes remain on the media

- Insoluble metals are not released

- More effective on some metals than other chemical reduction processes with no chemicals to handle

- Straightforward service and maintenance of AMRS system

Envirogen’s AMRS system is equipped with FerroLock™ zero valent iron media that can be employed for

applications with very low effluent limits for difficult to remove metals including selenium, chromium and arsenic.

AMRS pilot plant trials and lab scale testing

We do not believe there to be a “one size fits all” approach to ZVI treatment for the removal of heavy metals from wastewater and we’d always recommend pilot and/or lab scale testing to determine:

- Performance vs. contact time (full-scale system size)

- Media regeneration frequency

- Iron solubilisation rate and post-treatment requirements

An Envirogen field-based pilot and full scale AMRS system utilizing FerroLock ZVI media

Case study – Successful Coal Combustion Residuals (CCR) ash-pond clean-up pilot, East Coast USA

Discover how a pilot study for treatment of coal ash pond water demonstrates the effectiveness of the AMRS with zero valent iron to reduce selenium levels to single digit parts per billion, even when faced with the more difficult-to-treat species such as selenate.

Whitepaper – Evaluation of zero valent iron and other iron-based media for selenium reduction in water

Envirogen has completed extensive research and testing of various iron based media available in the market to understand the performance differences and to allow selection of the optimum zero valent iron media for each application. Results of that study can be found in our ZVI media evaluation whitepaper.