Hollow fiber membrane technology is an extremely versatile and effective method of removing contaminants from liquids. We offer a comprehensive range of hollow fiber membrane treatment skids, including ultrafiltration, microfiltration and nanofiltration technology.

The scale and adaptability of our range means that we can offer separation of particles from 0.6µm in diameter to as low as 0.001µm. This makes our hollow fiber membrane technology suitable for multiple applications across a wide range of industries.

What is hollow fiber membrane technology?

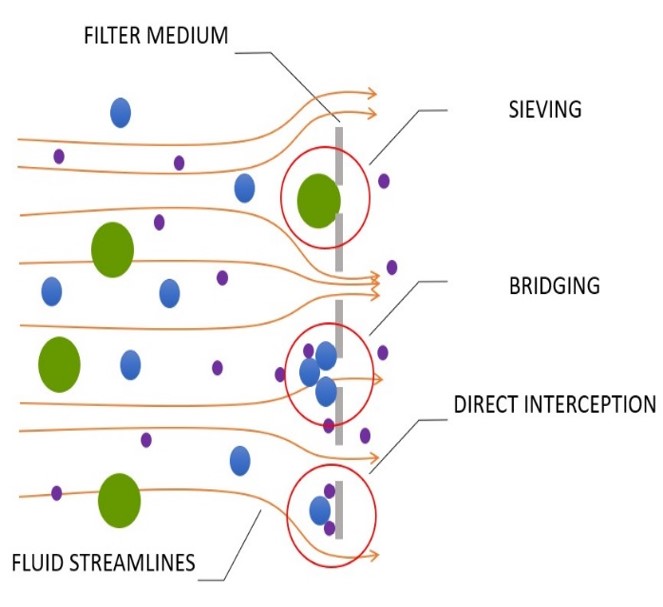

Hollow fiber membranes are fine filters that act as selective membranes to remove particles based on their size. The membrane surfaces feature fine pores that determine which particles will pass through based on a molecular weight cut-off value.

Typically, water and small dissolved particles will pass through the filter and the larger, solid particles will be retained and rejected. Although, in the case of nanofiltration, even smaller ions can be rejected due to the very small pore size and charged surface.

How does hollow fiber membrane technology work?

Hollow fiber membranes are inserted into robust, pressurised vessels, each arranged on a modular skid. The system can then be operated in one of two ways, depending on the liquid, the application and the quality requirements for the resulting filtrate.

An Envirogen hollow fiber membrane filtration system

Featured Case Study

Dead-end filtration

In dead-end operation, the full feed flow is directed to the hollow fiber membrane without the use of recirculation and without concentrate being removed. The suspended solids within the feed flow are deposited on the surface of the membrane, to form a cake layer which itself starts to act as a filter.

Dead-end filtration illustration

With no need to recirculate retentate, dead-end filtration reduces pumping demand, which lowers the amount of operational energy needed. Dead-end filtration is often used for liquids with lower particle loads. For higher particle loads, membranes with a high surface area can be used to maintain low flux rates and allow the filtration cake to form on the surface. The velocity of the feed flow and the surface area of the membrane needs to be carefully designed and controlled to prevent a deeper build-up of particulate matter. Failure to install a suitable amount of surface area can result in a deeper build-up of particulate matter resulting in higher transmembrane pressures and even irreversible fouling on the membrane.

Dead-end filtration is often the operating preference in ultrafiltration and is commonly used to treat surface waters or as a pre-treatment stage for further treatment processes.

Crossflow filtration

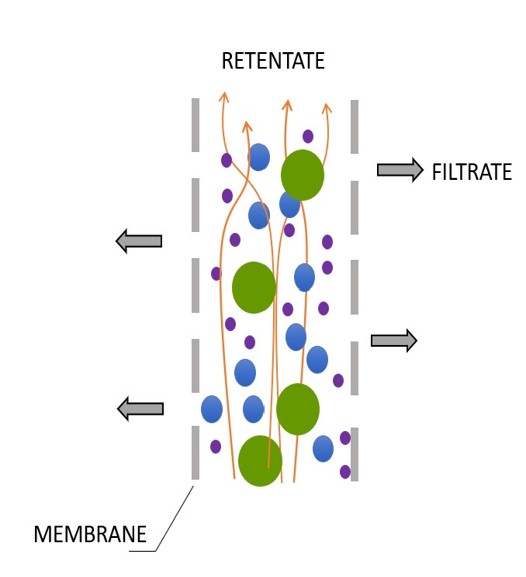

To enable a crossflow membrane configuration, a retentate return feed and a recirculation loop are created. The feed flow is sent to the membrane via a recirculation loop to maintain high velocity through the hollow fiber membrane lumen. Larger particles are retained within the retentate liquid and the smaller molecules can pass through into the filtrate. A small proportion of the filtrate is passed back to the feed vessel to prevent excessive levels of solids building up within the membrane lumen.

Crossflow filtration illustration

Once a crossflow velocity is achieved, the force of the retentate flow prevents particulate build-up on the membrane surface. By removing the build-up, trans-membrane pressures are reduced and longer batch runs can be achieved.

Crossflow filtration systems are often used in batch processes and for more complex and challenging feed streams. Microfiltration, using a crossflow configuration, is an ideal solution for product clarification and is widely used in breweries, wineries and in the production of cider, vinegar and fruit juices.

The energy requirements associated with achieving crossflow velocity mean that a limited amount of surface area can be installed while maintaining acceptable operational expenditure (OPEX) values for the lifecycle of the systems. Crossflow membrane units will generally have a reduced surface area which means there are fewer lumens to drive the process stream through, this means that lower flow rates result in higher velocity.

Speak to our team of experts to discover how you could save money, increase manufacturing efficiencies and reduce costs. We conduct free assessments to identify how you can improve your water treatment and process filtration systems

Hollow fiber membranes for a range of applications

There are three main types of hollow fiber membrane filtration, each offering its own benefits for different applications and each classified according to the molecular weight of the particles that it allows into the resulting filtrate.

We offer solutions based on each of these main types:

PureSep UF ultrafiltration technology

Envirogen’s PureSep UF range is operated in a dead-end filtration mode and uses 43m2 hollow fiber membranes in an inside to outside configuration to optimum back-pulse performance. Each hollow fiber membrane is constructed from a blend of hydrophilic polyethersulphone (PES) and polyvinylpyrrolidone (PEV), providing market-leading permeability rates. Available either as 150 kilodalton (kDa) or 10kDa molecular weight cut-off (MWCO) ratings, they deliver excellent removal of suspended solids, bacteria and log 4 reduction of viruses.

Our PureSep UF systems come ready-to-install in a compact skid design. Back-pulsing and chemically enhanced back-pulsing equipment are also supplied as standard.

For more information on PureSep UF and bespoke ultrafiltration technology, contact our expert team.

PureSep MF microfiltration technology

Our PureSep MF range of microfiltration technology is specifically designed for the clarification of alcoholic beverages, including beer membrane filtration, vinegar and fruit juices. Clarification can be achieved in just one step thanks to crossflow operation and extra-wide, 1.5mm lumen polyethersulfone hollow fiber membranes. With no additional additives or processing requirements, energy and labour costs are reduced. We offer two model ranges for specific clarification demands. Our PureSep MF 100 model is optimised for the clarification of wine, cider, vinegar and fruit juice, while the PureSep MF 600 model is specifically designed for beer clarification.

Find out more about PureSep MF and our bespoke microfiltration technology.

PureSep NF nanofiltration technology

Our innovative PureSep NF system takes filtration to a new level with its unique, direct nanofiltration hollow fiber membranes, manufactured from polyethersulfone. PureSep NF offers the additional benefit of reducing conductivity in feed streams by rejecting larger dissolved molecules, thanks to its 400 Dalton (Da) MWCO.

PureSep NF is a direct nanofiltration system and can be used as a single-step replacement for multiple process stages, including coagulation, clarification, sand filtration, ultrafiltration and reverse osmosis. Our nanofiltration plant has a low chemical requirement and delivers significant energy savings and carbon footprint reductions too, when compared with conventional technologies, such as reverse osmosis, adsorption and oxidation.

PureSep NF is an excellent choice for surface water treatment and waste stream recycling, providing rejection of dissolved solids with a fraction of the energy needed for comparable spiral wound reverse osmosis processes. Each hollow fiber membrane offers high fouling resistance with no pre-treatment.

For more information on PureSep NF and bespoke nanofiltration technology, contact our expert team.

Envirogen hollow fiber membrane products

We offer a range of hollow fibre membrane systems, each designed for specific applications:

For more information on PureSep NF and bespoke nanofiltration technology, contact our expert team.

PureSep UF – ultrafiltration membranes for excellent removal of suspended solids, bacteria and viruses greater than 10kDa or 150kDa in in molecular weight.

PureSep MF – for one-step clarification of alcoholic beverages, including beer membrane filtration, vinegar and fruit juice.

PureSep NF – replace coagulation, clarification, sand filtration, ultrafiltration and reverse osmosis with a single-step nanofiltration system.

Hollow fiber membrane technology case studies

Jamaican-based winery improves efficiency and productivity while reducing waste streams with Envirogen microfiltration technology.

Africa-based global tea producer achieves 65% process water recovery with Envirogen hollow fiber membrane ultrafiltration system.

Heineken reduces production timescales and operating costs for Bulmers cider manufacturing with Envirogen crossflow microfiltration technology.

When a leading industrial manufacturer wanted to grow its site operations, it was the perfect time to re-evaluate water recycling and reuse within its manufacturing process.

Speak to our team of experts to discover how you could save money, increase manufacturing efficiencies and reduce costs. We conduct free assessments to identify how you can improve your water treatment and process filtration systems