Energy from Waste (EfW) is an expanding industry that not only supplies electricity to the national grid but helps local authorities to minimise their use of landfill – and prevents heat from burnt waste literally “going straight up the chimney”. Instead, it heats boilers to produce steam that drives turbines that produce electricity.

Successful end-to-end EfW relies on a flow of household waste in, and electricity out. Between these two ends, boilers typically use biogas from anaerobic digestion of food waste, and gasification (by incineration) of general refuse waste, as their power source. Such systems are themselves part of a larger end-to-end process that can include recycling, the sale of electricity to the National Grid’s transmission network, and district heating and other waste solutions.

Key to the success of the generation of electricity is the maintenance and efficient operation of the boilers, which is fundamentally dependent on the proper management and treatment of water to produce high quality feedwater. Even new, state-of-the-art industrial boilers lose some water through steam leaks and other processes including blowdown. Blowdown is the process in which water is intentionally blown from a boiler to avoid concentration of impurities during continuing evaporation of steam.

In addition, crucial to the operation and efficiency of the boilers is the supply of demineralised, ultrapure water (UPW) – the required feedwater. Such water is essential for preventing buildup of minerals and impurities that can cause scaling and corrosion within the system. Without UPW, pipes and boilers become clogged with deposits, leading to increased frequency of leaks and blowdowns.

Added to these serious issues, which compromise system efficiency, the EfW operator has to cope with increased demand for water, which increases operational expenditure. These costs can be reduced by implementing water recycling and reuse technology (RR) which also provides the benefit of conserving water – crucial when the supply of water is diminished by drought – and reducing the associated costs.

Achieving UPW

An example of advanced water purification is Envirogen’s Eco MultiPro, a compact, all-in-one multi-technology RO-EDI plant. Crucially, it meets stringent operational requirements by producing treated water quality of <0.2 Microsiemens/cm, and <20 ppb Silica at up to 50m3/hr flowrate, without the use of hazardous chemicals common in older designs of demineralised water systems. Envirogen offers 5, 10, and 15 m3/hr flow rate models on a single skid, with up to 50 m3/hr being achieved where the GTM(s) and continuous electrodeionisation (CEDI) are supplied as a separate block for larger flows.

Full site audit of EfW plant including the water treatment system

Preceding a decision on the overall water treatment solution required, a full site audit will detail how specifications can be met optimally and cost effectively, over the long-term lifecycle of the equipment. Additionally, an audit can be utilised for the adoption of water-resilient business models, which can help to realise water savings and support the business continuity plan of an EfW plant.

FREE SITE ASSESSMENTS: Read our blog article on the importance of partnering with industrial water treatment companies and the benefits of complimentary site assessments.

An audit will discover bottlenecks and outdated processes, and give details about new alternatives – or upgrades, where appropriate – with projected payback and cost savings. Upgrades of old water purification systems are possible through refurbishment, which comes with its own set of pros and cons. The pros include short-to-medium term cost savings, the cons: more down time to be expected, depending on a number of factors, including overall quality of the refurb, the quality of its constituent parts, and any time spent on a lifecycle cost analysis (LCC).

If refurbishment is likely to cause significant downtime, there are ways to mitigate this. For instance, rental equipment or containerised mobile water services can be utilised, providing access to the latest water treatment technology while allowing work to proceed without major disruption during planned outages. Rental services can generally be made available for as long as needed. This requires careful project management and close collaboration between the plant and the water treatment company.

READ OUR BLOG: Temporary water treatment plants – a short-term fix with long-term benefits.

Older, conventional, resin-bed demineralisation solutions depend on on-site hazardous materials for chemical regeneration as part of the water purification process. One solution not requiring such materials is the state-of-the-art Eco MultiPro. In the context of the Eco MultiPro, “state-of-the-art” means a three-stage treatment process: reverse osmosis technology (RO), use of gas transfer membranes (GTMs), and CEDI, without the use of any hazardous chemicals on-site. With an anticipated design life of over twenty years, such systems complement new site builds and existing setups, and offer return on investment (ROI) and performance benefits when viewed from the perspective of LCC.

Between them, these stages remove all scale-forming ions to ensure optimal performance of boilers and low operating costs. To put that in context, heating water is energy-intensive, and scale formation reduces efficiency. If efficiency is improved, the heating requires less energy. Using hazardous chemicals means that firstly, space has to be found for the storage and handling of the chemicals. Secondly, health and safety precautions for operators must be implemented and strictly followed. And finally, the significant ongoing costs of the chemicals.

Additionally, regular deliveries of these chemicals by road contribute to increased CO2 emissions, which is a significant environmental concern and could negatively impact an EfW operator’s green credentials and corporate social responsibility (CSR) commitments.

Because the GTMs deployed in Eco MultiPro style systems are durable and long-lasting – i.e. high specification – they deliver considerable cost savings over conventional demineralisation equipment. Further, the RO-CEDI of the Eco MultiPro relies on only a small amount of electricity to renew its membranes. The entire demineralisation process carries a much lower operating cost compared to conventional resin-bed, chemicals-reliant solutions. Where the electricity supply is generated on-site, costs will be even lower.

Eco MultiPro RO-EDI plant, featuring RO membranes, CO2 degas membranes and electrodeionisation VNX modules.

Lifecycle cost analysis – and a link with reliability

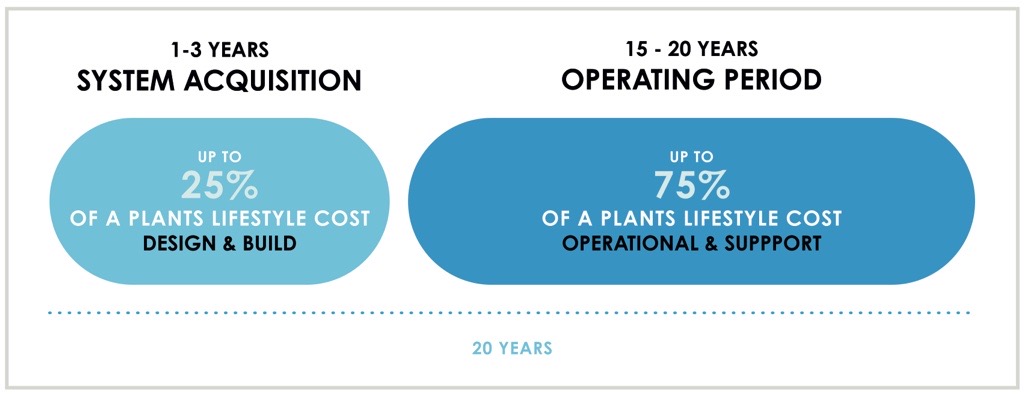

Complementing an audit should be lifecycle cost analysis (LCC) in order to examine in detail, and understand, the long-term costs of a project, not just of capital expenditure, and address issues associated with focusing solely on cap-ex costs.

Organisations often face challenges when making purchase decisions based solely on capital costs, because these decisions frequently rely on assumptions that do not materialise. For example, capital equipment may not meet its anticipated life expectancy and often lacks comprehensive performance warranties. Maintenance costs frequently exceed forecasts, chemical consumption, where used in resin-based equipment, is underestimated and downtime occurs more often than expected. Often, energy consumption and labour requirements are also higher than expected, and unforeseen compliance and landfill disposal issues may arise.

The complexity of construction materials, the type of influent, and other variables can significantly impact system delivery, performance, and long-term cost-efficiency. Between them, these factors create real difficulties when forecasting the end-to-end ROI of a project. These difficulties can be overcome with LCC.

LCC addresses the long running debate about capital expenditure (CAPEX) versus operating costs (OPEX), by focusing on the total cost over the life of the project (TOTEX). To be optimally effective, LCC should be allied to direction, oversight and on-site management, ideally achieved by a plant operator partnering with a water treatment specialist. An experienced, knowledge-driven specialist will have the understanding and tools to meet the specifications applicable to each phase of a plant’s design and operation, from sourcing of equipment and parts to maintenance and operational and work processes.

Envirogen’s extensive partnership experience has resulted in a methodology that includes allocating a value individually to CAPEX, OPEX and TOTEX. An effective combination of CAPEX and OPEX, TOTEX has emerged as a way to deliver, long term, a more realistic view of overall ROI than one where the focus is on CAPEX or OPEX alone.

LCC is strongly tied to the long-term reliability of an EfW plant, where robust equipment is crucial to optimal operation. Real-life LCC modelling demonstrates that investing in reliable, high-quality solutions reduces equipment failures and minimises their wider impact on plant performance.

As part of LCC, integrated systems and comprehensive services focus on both capital costs

and operating costs in order to reduce total life cycle costs

Remote monitoring and management

A key component of LCC is remote monitoring and management (RMM), which allows EfW operators to be in full control, with specialist support available if required. RMM helps to optimise performance, increase efficiency and prevent unplanned and costly shutdowns – and engineer callouts – through alerts for pro-active, preventative maintenance; and alerts for any unexpected issues not related to maintenance that may arise. To summarise, RMM can realise rapid ROI through cost savings on engineer callouts, improved site management and operational efficiency.

Top level remote monitoring systems comprise secure data transfer via resilient hardware and firmware, and high-grade data security including encrypted connections – wirelessly or by fixed line.

Prior to the audit and LCC stages come the planning, design, build and delivery of an EfW plant; these stages are managed by engineering consultants and construction companies. Although they are not involved directly in water treatment, the consultants will liaise closely with specialists in the implementation of water treatment systems and operational processes that deliver best LCC-driven value including ROI.

READ OUR BLOG: How a remote water monitoring system significantly reduced unplanned production downtime for a major soft drinks manufacturer.

To conclude…

EfW is a growing industry that depends on top tier, state-of-the art equipment and support – including warranties – for minimum downtime of pipework and the boilers that generate steam for the generators. “Top tier” does not automatically equate to “the most expensive”. When viewed from the perspective of LCC, the associated TOTEX and equipment reliability, cost efficiency and operational performance are competitive.

When addressing LCC, including the long-term implications of initial investments and the reliability of equipment to be purchased, partnering with experts in water treatment pays verifiable dividends. The EfW plant operator can make informed decisions that align with its long-term financial and operational performance objectives – including minimising the risk of failures and downtime.

See our EfW water treatment case studies…

- Energy Works Hull: Discover how Eco MultiPro prevented 240,000 tonnes of waste from reaching landfill.

- Surrey County Council: Learn how Eco MultiPro enables the conversion of waste into electricity.

- EfW Power Station: See how Eco MultiPro helps process 169,000 units of refuse-derived fuel (RDF) annually, supplying power to the UK’s National Grid.

For a free assessment to evaluate water treatment and process filtration solutions for your site, contact our team of expert engineers